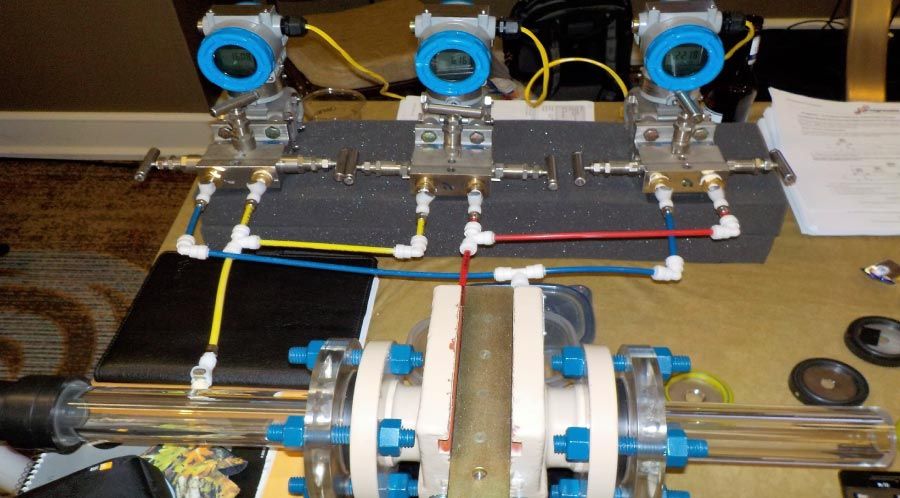

Tek-Sub 4800 Submersible Level Transmitters are designed to measure the liquid and slurries Level, along with monitoring the level of fluids. These devices have high precise piezoresistive sensor, stainless steel body, and waterproof cable, which makes them suitable for long term ideal service. Easy to install, clean, and almost no maintenance.

- Tek-Sub 4800A uses a high-quality ceramic pressure sensor packaged with PTFE housing that gives corrosion resistance in fluids.

- Tek-Sub 4800B is designed to measure the liquid and slurries Level, including a high precise piezoresistive sensor that offers accurate and reliable level measurement in numerous applications.

- Tek-Sub 4800C Borehole is 19 mm diameter, perfect for narrow conduit installation. The piezoresistive sensor is placed in a slim outer body that fits into boreholes, wells, and slender pipes.

- Tek-Sub 4800D has clog-free silicon piezoresistive sensor regulating liquid level without being affected by debris, manufactured for precise real-time level measurement with several standard outputs.

Features

- Temperature-compensated.

- Completely sealed, stainless steel.

- Highly durable with low maintenance.

- Factory calibrated with easy installation.

- Measuring Pressure range:Tek-SUB 4800A: 3 psig to 15 psig (2 mH2O to 10.5 mH2O).Tek-SUB 4800B and Tek-SUB 4800D: 5 psi to 20 psi (3.5 mH2O to 14 mH2O), Optional ranges available.Tek-SUB 4800C: 10 psi to 50 psi (7 mH2O to 35 mH2O), Optional ranges available

Accuracy:

Accuracy:

- Tek-SUB 4800B: ±0.25% FS

- Tek-SUB 4800A, Tek-SUB 4800C & Tek-SUB 4800D: ±0.5% FS.

Designed to meet the exacting standards for crude oil storage and transfer from lease tanks, MPX Series API 18.2 probes are built on robust 1”-diameter stems of either 316L stainless steel or Titanium 2, and use floats made to resist the buildup and fouling that come with operating in crude oil, all so you can trust the ±1 mm accuracy of the probe output. MPX Series API 18.2 probes also provide the averaged reading of submerged digital temperature sensors, each with ±0.25° C accuracy, so your system doesn’t have to do the math. With the MPX Series API 18.2, all interested parties get an accurate reading of the level and temperature of the crude oil in a lease storage tank.

Designed to meet the exacting standards for crude oil storage and transfer from lease tanks, MPX Series API 18.2 probes are built on robust 1”-diameter stems of either 316L stainless steel or Titanium 2, and use floats made to resist the buildup and fouling that come with operating in crude oil, all so you can trust the ±1 mm accuracy of the probe output. MPX Series API 18.2 probes also provide the averaged reading of submerged digital temperature sensors, each with ±0.25° C accuracy, so your system doesn’t have to do the math. With the MPX Series API 18.2, all interested parties get an accurate reading of the level and temperature of the crude oil in a lease storage tank.